LOCATION:HOME > PRODUCTS > Alumina ceramic pipe/Ceramic tube

LOCATION:HOME > PRODUCTS > Alumina ceramic pipe/Ceramic tube

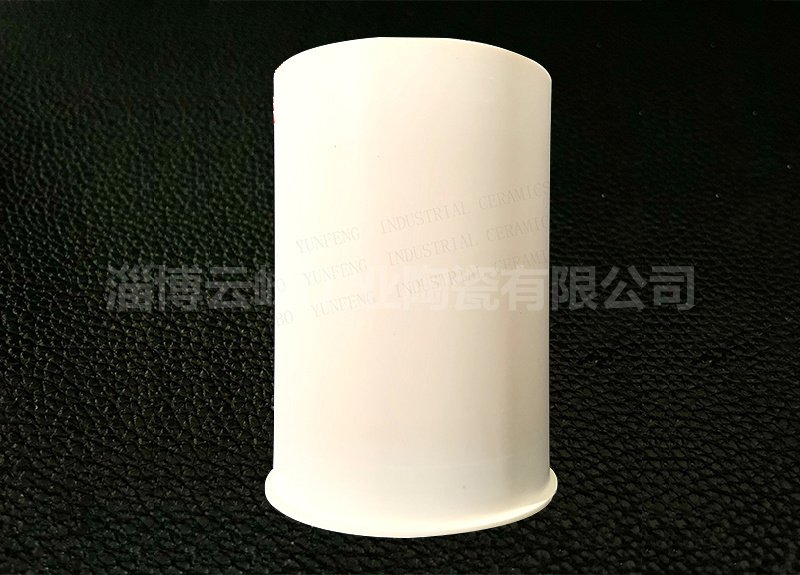

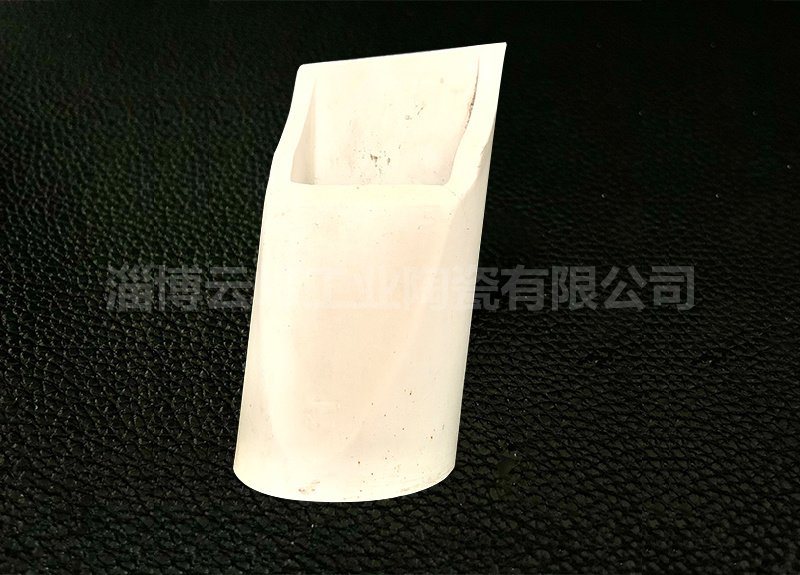

Alumina ceramic ring

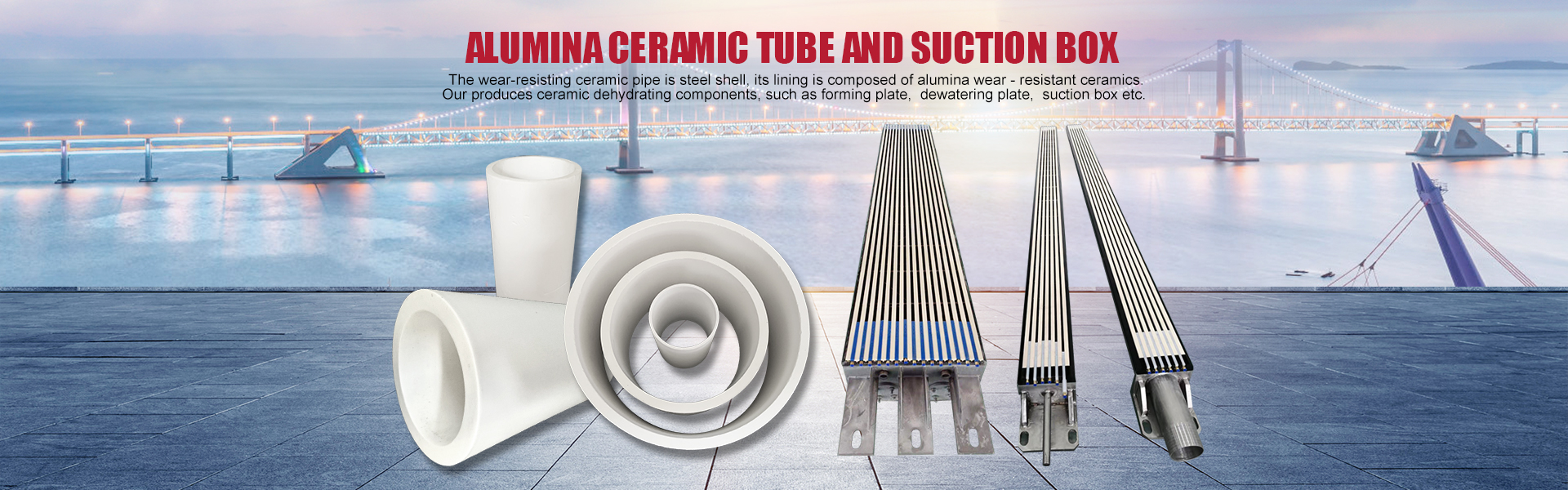

Fluid pipeline transportation is widely used in electric power, metallurgy, coal, petroleum, chemical industry, building materials, machinery and other industries.

When conveying materials with high grinding properties in the pipeline (such as ash slag, coal powder, ore concentrate powder, tailings cement, etc.), there is a problem of fast wear in the pipeline, especially in the bending pipe.

When the gas, liquid or solid with strong corrosiveness are transported in the pipeline, the pipeline will be corroded so that it will be destroyed quickly.

When conveying materials with high temperature in the pipe, it is very expensive to use heat resistant steel pipe.

Wear - resistant ceramic pipe on the market, these problems are readily solved.yunfeng

There are qualitative differences between wear-resistant ceramic pipe and traditional wear-resistant cast stone pipe, wear-resistant alloy cast steel pipe, bimetallic composite pipe, etc.

The outer layer of the wear-resistant ceramic tube is seamless steel tube, and the inner layer is special corundum ceramics. This corundum ceramic layer, which ranges from a few millimeters to dozens of millimeters, is the real reason for the wear resistance of the corundum wear-resistant tube.

The hardness (HAR) of this corundum layer is ≥90 and mohs hardness reaches grade 9, second only to diamond and silicon carbide, making it an ideal and economical wear-resisting material.

previous posts:Wear-resisting 95% Alumina Ceramic Lined Steel Tube Pipe

next chapter:Wear-resisting ceramic pipe is to use high temperature

Product Recommendations

-

Pulp high density cl...

-

High purity alumina ...

-

best price oxide cer...

-

Heavy medium cyclone

-

alumina ceramic line...

News Recommendation

- Whether alumina ceramics have the proper... Can alumina products be wiped with deter... How are alumina ceramics made by injecti...

- What are the technical parameters of 99.... Operation mode of slag eliminator How does the high concentration slag rem...

- How to solve the failure of slag remover How are alumina ceramic parts produced How are alumina ceramic powders formed a...

-

Zibo Yunfeng Industrial Ceramics Co., Ltd

Zibo Yunfeng Industrial Ceramics Co., Ltd

- A number of advanced products have been developed: structural ceramics and functional ceramics, products can be used in papermaking, chemical, scientific research, electronics, medicine, thermoelectricity and other industries, with wear resistance, corrosion resistance, high temperature resistance and other characteristics.

-

+86 0533-5556936

+86 0533-5556936

- MORE

鲁公网安备37030202001027

For the record,:ICP No. 2022001830-1 Technical support:ZBOK

鲁公网安备37030202001027

For the record,:ICP No. 2022001830-1 Technical support:ZBOK

paper cleaner

paper cleaner